Lean Blog Series - Part 2: Identifying Value in Lean

The Significance of Value in Lean Management

Lean management is sometimes perceived as a mindset that solely emphasizes efficiency. However, more importantly, it focuses on creating value. Efficiency certainly matters, but above all, a company must identify what creates value from its customers' perspective and what they are willing to pay for. This shifts the entire logic of efficiency thinking - in Lean management, it's not about running faster but about running smarter, more directly towards the goal.

It's important to understand this philosophy as a long-term exercise that gradually changes actions so that they can produce what the customer values. I call it a philosophy because ultimately, it refers to the underlying logic of the entire operation, not just improving performance on individual tasks. In the first part of the blog series, Lean principles were introduced, which gradually transform the company's operations to be more value-centric.

What is value then? In Lean, value is often defined not only from the perspective of creating value for the customer (value is what the customer is willing to pay for) but also inversely, by what it is not. The ability of a process to create value improves when sources of waste are systematically eliminated, i.e., when value is not wasted on unnecessary activities (or waiting!).

Sources of Waste in Lean Management

In classical Lean literature, there are seven sources of waste, and in recent years, an eighth waste has been added. This last one will have its own discussion in the blog series, in the final part, so it will not be extensively covered here.

The sources of waste that Lean thinking aims to eliminate from processes are:

-

- Unnecessary motion

- Unnecessary transportation

- Overprocessing

- Overproduction

- Inventory

- Waiting

- Defects/inspection

- Lost information/talent

Sources of waste 1 (unnecessary motion), 2 (unnecessary transportation), 4 (overproduction), and 5 (inventory) are of a nature that may not be as strongly manifested in the non-physical goods world. However, even in service production, where a customer arrives at a service point, at least the first two can be applied. Solutions often involve some kind of single point of contact service points, minimizing customer effort and speeding up the service experience. Usually, services cannot be stocked, but there are exceptions to this rule.

Overprocessing is one of the most crucial sources of waste from the perspective of this blog. Overprocessing covers all activities in a process that do not actually contribute to the direction valued by the customer. The key to eliminating overprocessing lies in understanding the customer's preferences precisely. Efforts should be made to actively identify those factors that create value for the customer, so that operations can be focused on delivering these. This also relates to a practical tool introduced later in this blog post.

Waiting is a source of waste that may initially seem like a necessary part of operations. In many cases, not everything can be available instantly when the customer desires it. However, operations can be organized in various ways, and from a Lean perspective, the focus should be on maximizing the flow of value to the customer. Therefore, ideally, services should be available to the customer at the time that best suits their needs. Especially in digital services, this is often easily achievable.

Example:

If, for instance, you offer a software product that requires some learning, you can provide basic technical training with ready-made, high-quality videos and offer a shorter Q&A session related to them at a time convenient for the customer, booked through an online calendar.

Suppose you previously offered this service by scheduling a 2-hour initial training session based on the trainer's available time, and the implementation often extended to 2 weeks due to time constraints. In the Lean process, the customer essentially receives the same knowledge through videos and a separately booked, but shorter (30-minute) Q&A session. 30-minute time slots are typically easier to find in a busy trainer's calendar and closer in time.

This way, the turnaround time for this (onboarding) subprocess was reduced from, for example, 2 weeks to two days. The customer seemingly gave up a bit of the service offered directly to them but received the needed service much faster in return. Most likely, this exercise increased their perceived quality and satisfaction. Of course, following the same logic, the next step could be aiming for training-free, completely intuitive adoption, but that would be a matter for further development!

Defects and inspection are also essential aspects from the Lean perspective. The basic idea is that each task should be done right the first time. Correcting a faulty product or service and even inspecting whether the service was faulty are wastes from the perspective of process benefits. By standardizing the process, progress can be made gradually towards a more perfect service capability, although it should be kept in mind that when humans are involved in the process, errors can occur. One key is to increase automation, which helps deliver customer value with minimal variance.

Wasted information and talent are, as mentioned, newer additions to the Lean canon, and they will be discussed in a future blog, so we won't cover it extensively here.

Identifying Process Parts that Create Value

For the sake of simplification, let's assume that you have already organized your operations in a process-oriented manner to create value for your customers, rather than functioning based on functions. Let's do a small exercise.

- Take out a process description of any central process serving your customers. Has the process description been developed to distinguish subprocesses or even their phases?

- Now, here's the key question: which parts of the process can be eliminated without reducing customer satisfaction? Can you identify stages where skipping them doesn’t significantly detract value for customers

- If the previous section identified non-value-added (NVA) stages, you can symbolically mark them with a red line in the process description, indicating that these stages should be eliminated either through automation or by redesigning work. Automation may incur certain costs, but if it helps remove a step from the process that doesn't add value for the customer, it can be highly profitable. The same applies to re-designing work. The key here is whether the customer value-adding parts of the process (marked here with a traffic light code as green) can be combined in a temporal logic, so that the process doesn't need to go through the "red" operation described as not value-adding at all.

- Sometimes it's found that a process step identified as not value-adding in the previous phase is actually essential but non-value-adding. These could be, for example, tax or contract-related matters that must be handled even if they don’t directly add value. These essential non-value-added (ENVA) functions should be streamlined through automation, but by definition they cannot be entirely eliminated.

- Have you now color-coded all parts of the process as either red, yellow, or green? As a checklist, consider the following requirements: in value-adding parts, the product or service is transformed (input is processed), the customer is willing to pay for this change, and the work is done right the first time (no need to search for errors and correct them).

Practical Exercise: Building a Value Compass

Next, let's implement a practical tool for developing Lean processes. Every company's processes are different, but you'll surely grasp the idea. This exercise is suitable, for example, as a Kaizen group exercise introduced in Part 1 of the blog series, if you have a moment to spare for identifying improvement opportunities. I encourage you to involve the owner of the process to be developed and practical workers, if not even customers. Through the group exercise, process value creation bottlenecks can be identified and ways to address them can be found.

- Choose the process to be developed. Note that here we mean a customer process from at least order to delivery. If desired, you can expand the perspective to marketing and sales stages or after sales stages (the first process as an introduction to continuous customer relationship and growth).

- Name the process stages. Consider temporal logic and forget about exceptions at this stage, i.e., rare cases (e.g., less than 5% of all cases). So, what does the typical customer order flow through the process look like?

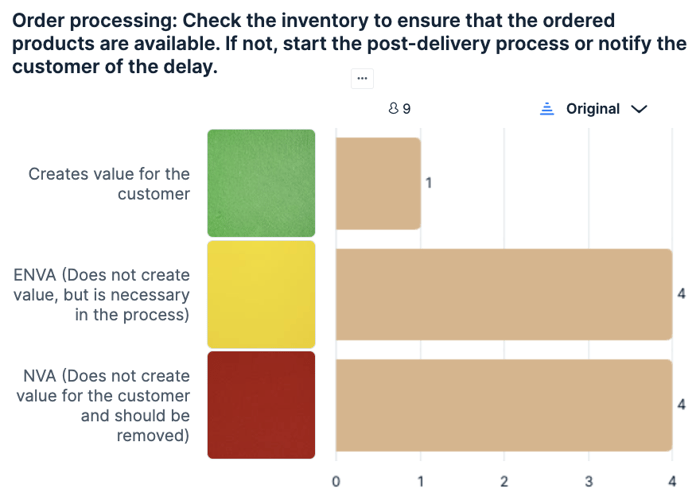

- Enter the process stages into the survey tool or another platform you use for structuring. The idea is that each participant in the assessment evaluates for all process stages whether it adds value (green), whether it's a necessary non-value-adding stage (yellow), or whether it's a non-value-adding part of the process (red). The answers are compiled, and the group discusses the results until consensus is reached on the colors for different stages. If a particular stage is interpreted as an NVA or ENVA stage, more detailed reasonings are requested. Below is an example of a survey template where the mentioned assessment can be made - ask for a free Value Compass survey template if you're using Zeffi.

Figure 1: The idea of the Value compass survey is to score the process steps as a basis for discussion and to get ideas about automation or work reorganization

Figure 2: The report of the Value compass survey serves as a starting point for a discussion of values related the process steps.

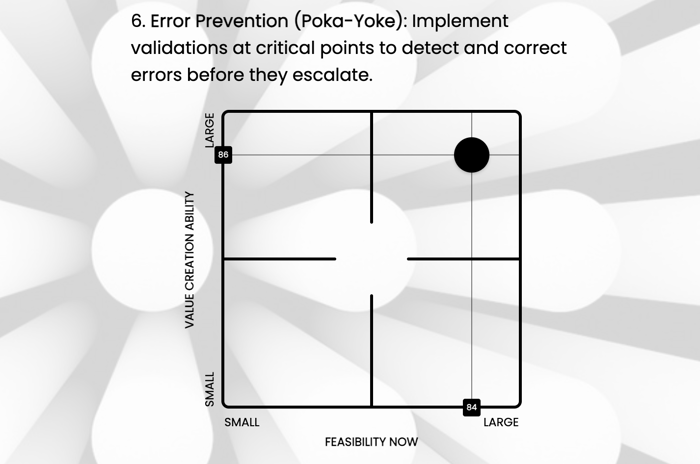

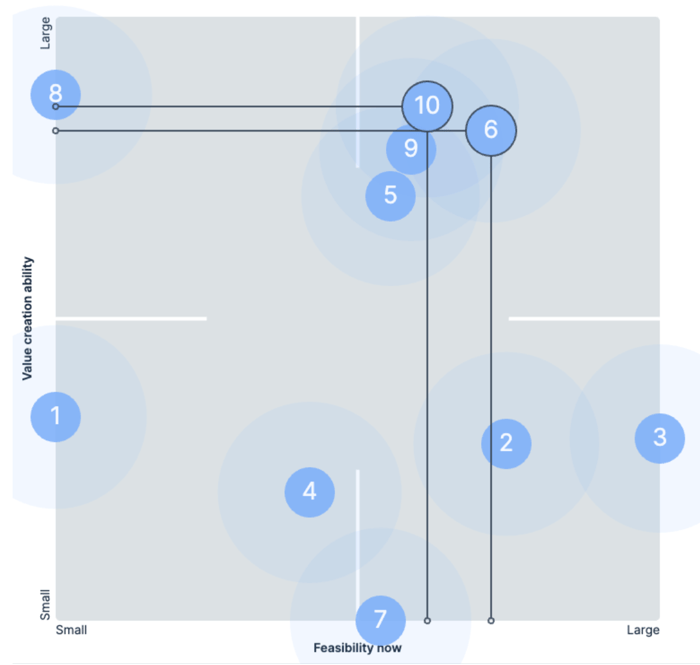

- Now, let's move on to development. The group selects a limited number of stages marked in red as focus areas, e.g., one or two, for which an A3 assessment is made. In Lean an A3 assessment is simply a plan on a sheet of paper that size (A3) outlining the measures and monitoring mechanisms, the timeline, and (important!) the responsibility of who is in charge of fixing this point. If there are many potential improvement areas, these can be assessed for attractiveness and feasibility of implementation. Below is an example of a survey template where such an assessment can be made - ask for the Lean Initiative Selector template if you're using Zeffi.

Figure 3: The Lean initiative selector can be implemented, for example, by evaluating the value creation ability (attractiveness) and feasibility of development measures, in this example simultaneously. Figure 4. Selection of prioritized development targets is easy after Z-scoring, in this example case relatively the most interesting items are Value Stream mapping (item 10) and Poka-Yoke (item 6).

Figure 4. Selection of prioritized development targets is easy after Z-scoring, in this example case relatively the most interesting items are Value Stream mapping (item 10) and Poka-Yoke (item 6).

- With these steps, value-creating parts of the chosen process were identified and described to the Kaizen group, along with actions to develop this process. Lean management is about small actions for better profitability and customer focus in a company. So, let's try it out!

That's all for now - in the next part of the blog series in week 13, we will discuss Lean from the perspective of quality assurance and the practical tools supporting it.

Regards,

Janne Vainikainen, Zeffi, COO, Lean Six Sigma Black Belt

ps. Would you like to get notified when our next blog on Lean is published? Subscribe>>

Blog Series Overview:

- Part 1: Lean Management in Practice

- Part 2: Lean Tools for Identifying Value

- Part 3: Lean Tools for Ensuring Quality

- Part 4: The 8th Waste of Lean - Lost Talent or Knowledge